How We Do It

Our Building Process

Victory keeps breaking paradigms each year. In the last 20 years our prime materials (fiber, resin, foam) have evolved at the same rate as the computer. Today having a heavy boat is not the equivalent of resistance and proper navigation rather its a synonym for inefficiency. Heavy boats strain the boats’ motor because they need more fuel and power in order to navigate resulting in less miles and more fuel consumption.

Victory keeps breaking paradigms each year. In the last 20 years our prime materials (fiber, resin, foam) have evolved at the same rate as the computer. Today having a heavy boat is not the equivalent of resistance and proper navigation rather its a synonym for inefficiency. Heavy boats strain the boats’ motor because they need more fuel and power in order to navigate resulting in less miles and more fuel consumption.

Why is the Victory Unsinkable?

Victory’s deck is self-draining

When there is water on deck, including rain or sea water, it is drained by Victory’s sides and floor covers since the Victory’s bilge is dry and has the finest technology to completely avoid water accumulation.

Foam filled hull with polyurethane with closed cells

There is a physics law that states that “two bodies are not capable of occupying the same space at the same time.” A Victory’s bottom is injected with 35ft^3 – 70 ft^3 of polyurethane foam in individual compartments with a special process to avoid water absorption. This guarantees a positive buoyancy in every situation, including: head overturned or a tear in the bottom.

Dry bilge: Hygiene and safety

The bilge is usually the boat’s junk yard collecting small debris, hair, fish scales, and food leftovers.

Victory’s bilge is completely dry since every opening leads to a draining system that drains the water. This includes the fish locker, anchor compartment, and floor.

Boat’s weighs less than water

The vacuum infusion lamination with Divinycell foam makes the weight of the material around 1300 lbs for ft^3, which is less than water. Therefore, if we were to cut a piece of a Victory’s bilge and chuck it at the sea, it would still float.

Latest Tech and Manufacturing Quality

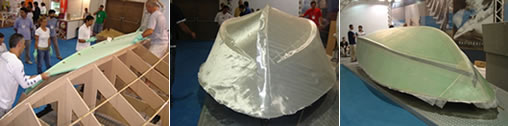

Benefits of Vacuum Infusion Lamination

We are proud to say that we are the only ones in Brazil manufacturing fishing boats bigger than 24 ft in series. The benefits include:

- High prime material quality – The vacuum infusion lamination requires top quality materials in order to work. Therefore we use special resin and fabric that uses Divinycell foam and more to achieve those high standards

- Weight – Using a regular method for lamination, the spray up or the hand lay up quantity of resin used X quantity of fiber applied is 8.8 to 2.2, meaning that for every 2.2 lbs of fiber one has to provide 8.8 lbs of resin. The resin alone acts like glass, it does not provide any structural resistance. To better comprehend the concept, let’s compare it to a concrete beam. The rebar inside the beam provides the same function the fiber does with the resin, therefore, without the rebar the beam will break. With the vacuum infusion technology, the quantity applied reduces to 2.2lbs to 2.2lbs. With this new technology, for every 2.2lbs of fiber there is 2.2 lbs of resin. This is effective since we use the combination of fiber and Divinycell foam, avoiding the use of additional resin.

- Tougher structural resistance – Our process does not only guarantee lighter weight, but also a more qualified structural resistance. Depending on the boat’s location, this can be up to 5 X more resistant.

- Lamination Thickness Homogeneity – With this process we guarantee a maximum variation of thickness lamination 3% or less throughout the same surface, making sure that each finished boat leaves with not more than a 2% weight difference

- Environmental friendly – The emission of styrene monomer into the atmosphere during the lamination process is completely eliminated. In addition, our fishing boats are “wood free” since it uses Divinycell foam. The boat hull, the structure of spars caves and lids are produced exclusively following the Divinycell foam infusion procedure.

High Quality

Divinycell Foam

The glass from the stern, sides, and bottom of a Victory are laminated with divinycell foam which reassures less future upkeep and care than wood since those tend to rot.

Resins

The resin used for vacuum infusion is special and can only be made from high quality prime material, non recyclable, in order to insure more resistance and flexibility avoiding chicken feet.

Premium Gel Coat

The gel coat is the white outer layer of the fishing boat, that isolates the laminated layer from the water and protects it from chemicals, hydrolysis, and UV rays. We use Norpol Isofitálico NPG / UV, which is only used by the top boat manufacturers in the world.

Fiberglass

Our fabrics are biaxias we do not use fio rowing in our manufacturing process. Our fuel tanks are certified by ISO9001

Tanks

The gasoline tanks are EPA certified.

Hardware

Our hardware is made from stainless steel AISI 316

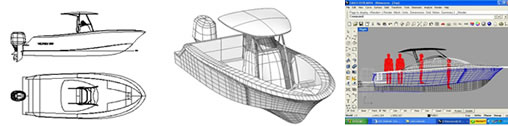

Cutting Edge Software

All of our projects are developed with softwares with the most current technology. From the 3D designs to the structural resistance tests and thin elements. All of the prototypes are developed and built with cuts created by CNC machines.

Prototypes

We are proud to have our own unique designs and develop our own models from scratch. We make sure to test if our models uphold our quality and safety standards with multiple tests before releasing it to the market, just like the automobilistic industry does. By using this testing method, we guarantee that once the product is released, our final product will surpass all our high quality standards.

Mold

Our molds are produced with the most resistant materials making the final product free from imperfections.